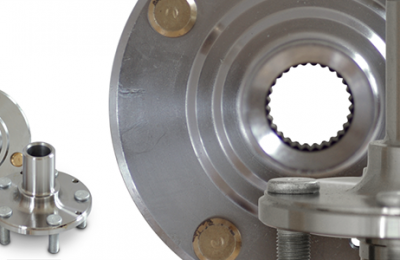

A Pipe fitting is used in pipe systems to link directly pipe or tube segments, to evolve to various dimensions or forms, and for other reasons, such as controlling or calculating liquid circulation. The word pipes is often used to explain high-performance (e.g. underhand, great circulation, warm, dangerous materials) conveyance of fluids in specific applications. The word tube is sometimes used for lighter-weight pipes, especially kinds that are versatile enough to be provided in coiled form.

A pipe nipple is a length of straight pipe with male threads on both sides. It is one of the most popular classification of pipe accessories. It is a plug or a coupling threaded on both sides. Pipe nipples are used to allow water applications to get connected to a hot water heating unit or other water plumbing. They are used to fit straight end water hose or pipe. A combination of pipe nipples are recommended for low-pressure release and suction power support for various fitting fluids and not for unstable items like air, nitrogen or vapor.

Types of pipe nipples

- Barrel nipple: This is a kind of a short tubular with a blend line outside at each end and which is un-threaded in the middle.

- Weld nipple: Weld nipple is used as another method of linking tube accessories. These kind of nipples are fitting for use under dimensions of vibrations, stress rises and changes of heat range.

- Swage nipple: The basic purpose of a swage nipple area is to providing the circulation of fluids from one pipe dimension to another. These are available with simply, beveled or threaded finishes.

- Hexagon nipple: Hexagon nipples are available in a number of discussions, components and measures.

Sizing

Once the kind of fitting required has been identified, the most essential aspect of pipe fitting can be addressed: appropriate dimension. Proper dimension is essential to successful fitting choice, as extra-large or small parts will either be completely not compatible or will closure or link insufficiently. Sizes for accessories are typically given in millimeters (mm) or inches (” or in) based and depending on the system of measurement. Proper dimension requires the consumer to choose fitting which is scaled using a process of statistic (Metric or English) that works with the equipment or set up being fixed.

Market Trends

Pipe fitting production and material requirements are application-dependent. Customer assessment with the providers of pipe accessories is common for marketing of component choice. There are certain safety and environment related issues experiencing the pipe fitting market. This is key point impacting buyers to choose or buy only quality items and the best accessories for specific programs. Pipe accessories producers are replying by dedicating more time and resources to support and repair.

The working pressure of pipe nipples will be different with the dimensions and development of the pipe, the kind and number of clamps used, secure positioning, appropriate setting up clamps, heat range and item being communicated. Pipe fittings and nipples are available in the largest wide range of wall thicknesses and components in the market.